Plywood Chair Design and Construction

Plywood is a versatile material that offers a cost-effective and durable solution for building furniture. Its layered construction provides strength and stability, making it ideal for crafting dining chairs. This guide explores the advantages and disadvantages of using plywood for chair construction, presents various design ideas, and provides a step-by-step guide for building your own plywood dining chair.

Plywood Chair Design Considerations

Plywood’s unique properties offer both advantages and limitations when used for chair construction.

- Benefits:

- Cost-effective: Plywood is generally more affordable than solid wood, making it an attractive option for DIY projects.

- Durability: The layered construction of plywood provides strength and stability, making it suitable for furniture that will withstand regular use.

- Easy to Work With: Plywood is relatively easy to cut, shape, and assemble, making it a beginner-friendly material for woodworking.

- Wide Variety of Finishes: Plywood can be stained, painted, or varnished to achieve a variety of aesthetic looks.

- Limitations:

- Weight: Plywood can be heavier than some other materials, which may affect the overall weight and stability of the chair.

- Limited Bending Potential: Plywood can be difficult to bend without compromising its structural integrity, which may limit design options for curved or contoured pieces.

- Susceptibility to Moisture: Plywood can be susceptible to moisture damage, so it is important to seal and protect it properly.

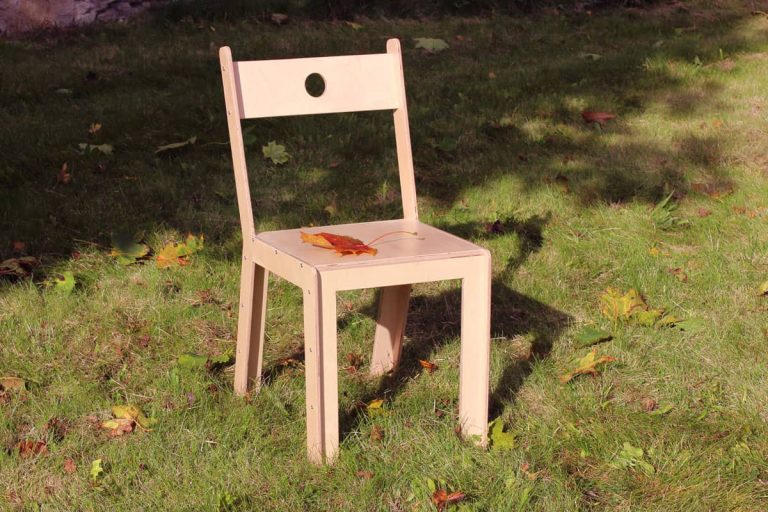

Plywood Chair Design Ideas

The design possibilities for plywood chairs are endless, ranging from simple and minimalist to intricate and ornate.

- Mid-Century Modern: These chairs often feature clean lines, tapered legs, and a minimalist aesthetic. The use of plywood allows for the creation of thin, elegant curves, characteristic of this style.

- Scandinavian: Scandinavian design emphasizes functionality and simplicity, often incorporating natural materials like wood. Plywood chairs in this style are typically lightweight, comfortable, and feature a minimalist design.

- Industrial: Industrial design incorporates raw materials and exposed elements, often featuring metal accents. Plywood chairs in this style might incorporate metal legs or hardware, creating a rugged and utilitarian look.

- Rustic: Rustic design emphasizes natural textures and imperfections, often incorporating reclaimed or salvaged materials. Plywood chairs in this style might feature a distressed finish or exposed grain, creating a warm and inviting feel.

Cutting and Assembling Plywood Chair Components

Building a plywood chair involves precise cutting and assembly of individual components.

- Cutting: Use a table saw or circular saw to cut plywood panels into the required shapes. Measure and mark the plywood carefully to ensure accurate cuts. For intricate designs, consider using a jigsaw or scroll saw for precise cuts.

- Joining: Use wood glue and screws or dowels to join the individual components of the chair. For strong and durable joints, consider using pocket hole screws or mortise and tenon joints.

- Sanding: Sand the chair thoroughly using progressively finer grits of sandpaper to create a smooth and even surface. This will help to prepare the chair for finishing.

Creating Comfortable and Durable Seats and Backs

Plywood can be used to create comfortable and durable seats and backs for dining chairs.

- Seat Construction: For a simple seat, use a piece of plywood that is slightly larger than the desired dimensions. For a more comfortable seat, consider layering plywood with foam padding and upholstery fabric. The use of plywood provides a strong base for the padding and upholstery.

- Back Construction: Plywood can be used to create a variety of back designs, from simple straight backs to contoured or curved backs. For curved backs, consider using a plywood bending technique or incorporating multiple pieces of plywood to create the desired shape. Plywood can also be used to create a slatted back design, providing a more breathable and visually interesting option.

Designing a Unique Plywood Dining Chair

To create a unique plywood dining chair, consider incorporating elements of different design styles or experimenting with unconventional shapes and materials.

- Materials: Consider using different types of plywood, such as birch plywood, maple plywood, or walnut plywood, to create a unique look. Experiment with different finishes, such as stains, paints, or varnishes, to achieve the desired aesthetic.

- Shapes: Explore unconventional shapes for the seat, back, or legs. Consider using curves, angles, or geometric patterns to create a visually interesting design. For a more modern look, incorporate thin, tapered legs or a cantilevered design.

- Accents: Add decorative elements, such as metal accents, leather straps, or fabric upholstery, to enhance the chair’s aesthetic appeal. These elements can add a touch of personality and sophistication to the design.

Essential Tools and Materials

Building a plywood dining chair requires a range of tools and materials. The specific tools and materials needed will vary depending on the design and complexity of the chair. However, some essential tools and materials are common to most plywood chair construction projects.

Essential Tools

Having the right tools is crucial for building a sturdy and aesthetically pleasing plywood chair. The tools listed below represent a comprehensive set for most plywood chair projects.

- Table saw: A table saw is essential for cutting plywood sheets into precise shapes and sizes. It allows for accurate cuts and consistent results, making it a valuable tool for creating the chair’s components.

- Circular saw: A circular saw is useful for making curved cuts and for cutting larger pieces of plywood that may not fit on the table saw. It offers versatility and mobility for cutting various shapes.

- Jigsaw: A jigsaw is ideal for making intricate cuts, especially when dealing with curved shapes or tight corners. Its ability to maneuver around complex contours is essential for creating the chair’s design elements.

- Drill: A drill is necessary for creating pilot holes for screws and for drilling holes for dowels or other joinery methods. It provides the necessary precision for assembling the chair’s components.

- Screwdriver: A screwdriver is essential for fastening the chair’s components together. Having a variety of sizes and types of screwdrivers ensures compatibility with different screw sizes and heads.

- Clamps: Clamps are essential for holding pieces of plywood together while gluing or screwing them. They provide secure and even pressure for strong and lasting joints.

- Sandpaper: Sandpaper is used to smooth out rough edges, remove imperfections, and prepare the plywood for finishing. Different grit sandpaper is used for different stages of sanding, from coarse to fine.

- Measuring tape: A measuring tape is crucial for ensuring accurate measurements when cutting and assembling the chair. It allows for precise dimensions and avoids errors in the construction process.

- Pencil: A pencil is used for marking cutting lines on the plywood and for transferring measurements. It ensures accurate and consistent markings for precise cuts.

- Safety glasses: Safety glasses protect your eyes from flying debris during cutting and sanding operations. It is essential for ensuring eye safety while working with woodworking tools.

- Dust mask: A dust mask protects your respiratory system from sawdust and other airborne particles generated during cutting and sanding. It is important for maintaining good health while working with wood.

- Ear protection: Ear protection is necessary for protecting your hearing from the loud noise generated by power tools. It prevents hearing damage and ensures a comfortable working environment.

Types of Plywood

Plywood is a versatile material suitable for chair construction. Different types of plywood are available, each with unique characteristics and suitability for specific applications.

- Sanded plywood: Sanded plywood is a common choice for chair construction due to its smooth surface and consistent thickness. It is available in various grades, with higher grades offering a smoother finish and fewer imperfections.

- Baltic birch plywood: Baltic birch plywood is known for its high quality, durability, and aesthetic appeal. It is often preferred for furniture construction due to its smooth surface, consistent grain, and strength.

- Marine plywood: Marine plywood is designed for use in wet environments, making it a suitable choice for outdoor furniture. It is treated with waterproof glue and is resistant to moisture and rot.

Wood Finishes

Choosing the right wood finish for your plywood chair is essential for protecting the wood, enhancing its appearance, and achieving the desired aesthetic.

- Paint: Paint is a versatile and affordable option for finishing plywood chairs. It offers a wide range of colors and finishes, allowing for customization and creative expression. Paint can be applied with a brush, roller, or spray gun, providing flexibility for different application methods.

- Stain: Stain is a liquid finish that penetrates the wood’s pores, enhancing its natural grain pattern and color. It offers a more natural look than paint and allows the wood’s beauty to shine through. Stain is available in various shades and colors, allowing for a personalized finish.

- Varnish: Varnish is a protective coating that creates a hard, glossy finish on the wood. It protects the wood from scratches, spills, and moisture, enhancing its durability and longevity. Varnish is available in different gloss levels, from matte to high gloss, allowing for a customized finish.

- Polyurethane: Polyurethane is a durable and water-resistant finish that offers excellent protection for plywood chairs. It is available in both oil-based and water-based formulations, each with its advantages and disadvantages. Oil-based polyurethane provides a more durable finish but takes longer to dry, while water-based polyurethane dries faster but may not be as durable.

Preparing Plywood for Finishing, Diy plywood dining chair

Properly preparing the plywood before applying a finish is crucial for achieving a smooth, even, and long-lasting finish.

- Sanding: Sanding the plywood surface is essential for removing any imperfections, scratches, or rough edges. Start with a coarse grit sandpaper to remove any major imperfections and gradually progress to finer grits for a smooth finish. It is important to sand in the direction of the wood grain for a consistent and even surface.

- Cleaning: After sanding, it is essential to clean the plywood surface thoroughly to remove any dust or debris. Use a tack cloth or a damp cloth to wipe down the surface, ensuring a clean and dust-free surface for the finish to adhere properly.

- Applying a sealer: Applying a sealer before the final finish can enhance the finish’s durability and prevent the wood from absorbing too much of the finish. A sealer creates a barrier between the wood and the finish, allowing the finish to adhere better and last longer. It also helps to even out the wood’s surface, making the final finish smoother and more uniform.

Shopping List

Here is a comprehensive shopping list for all the necessary materials for building a plywood dining chair. The specific materials needed will vary depending on the design and complexity of the chair.

- Plywood: Choose the appropriate type of plywood based on the chair’s design and intended use. Consider the thickness, grade, and size of the plywood sheets required for the chair’s components.

- Hardware: This includes screws, dowels, glue, and other fasteners needed to assemble the chair. Choose the appropriate size and type of hardware based on the chair’s design and the type of wood used.

- Finishing supplies: This includes the chosen wood finish, sealer, sandpaper, tack cloth, and any other supplies needed for preparing and finishing the chair. Choose the appropriate finishing supplies based on the desired aesthetic and the type of wood used.

Tips and Techniques for Success: Diy Plywood Dining Chair

Building a sturdy and aesthetically pleasing plywood chair requires careful consideration of various factors. From ensuring structural integrity to achieving a smooth finish, several tips and techniques can significantly enhance the outcome of your project.

Selecting Appropriate Hardware and Fasteners

The choice of hardware and fasteners plays a crucial role in the chair’s overall strength and durability.

- Screws: Select screws that are long enough to penetrate both pieces of plywood being joined and provide adequate holding power. Consider using countersinking screws to create a flush finish.

- Wood Glue: Apply wood glue to all joints before fastening with screws. Wood glue adds strength and prevents the wood from splitting.

- Joints: Use strong joints like mortise and tenon, dovetail, or lap joints for increased stability. These joints require precise cutting, but they significantly enhance the chair’s structural integrity.

Techniques for Creating Smooth, Professional-Looking Edges

Smooth, professionally finished edges contribute significantly to the chair’s overall aesthetic appeal.

- Sanding: Sanding is essential for creating smooth edges. Use progressively finer grit sandpaper to remove any rough edges or imperfections. Start with a coarse grit sandpaper and gradually work your way up to a fine grit for a smooth finish.

- Edge Banding: Edge banding is a technique for covering exposed plywood edges with a thin strip of veneer or wood. This enhances the chair’s appearance and protects the edges from damage. It can be applied using iron-on edge banding or by using wood glue and clamps.

- Router: A router can be used to create decorative edges or to smooth out rough edges. However, this requires practice and caution. Always wear safety glasses and use a router table for increased stability and safety.

Techniques for Sanding and Finishing Plywood

Sanding and finishing plywood are crucial steps in achieving the desired aesthetic and protecting the wood.

- Sanding: Sand the entire surface of the chair with progressively finer grit sandpaper to remove any imperfections and create a smooth surface for finishing. Start with a coarse grit sandpaper and gradually work your way up to a fine grit.

- Finishing: Apply a finish to the chair to protect it from moisture and enhance its appearance. Consider using a stain to add color, followed by a sealant for protection. A variety of finishes are available, including oil-based polyurethanes, water-based polyurethanes, and waxes.

- Safety Precautions: When sanding and finishing, wear a respirator mask to protect yourself from dust particles. Work in a well-ventilated area and follow the manufacturer’s instructions for the finishing products you are using.

Troubleshooting Common Problems

During construction, you may encounter some common problems.

- Uneven Legs: Uneven legs can cause the chair to wobble. To fix this, adjust the length of the legs using a saw or a sander until they are all the same length.

- Loose Joints: Loose joints can be tightened by adding more glue or by using longer screws. Make sure to use a countersinking drill bit to avoid splitting the wood.

- Splits in the Wood: Splits in the wood can be caused by using screws that are too long or by not using a countersinking drill bit. To fix this, use wood glue and clamps to secure the split.

A DIY plywood dining chair can be a great way to add a personal touch to your dining space. If you’re looking to give your chairs a more polished look, consider adding some round back dining chair slipcovers.

They can easily transform the look of your chairs, adding a splash of color or a more formal touch to your dining room. Once you’ve finished your DIY plywood dining chairs, you’ll have a unique and comfortable set to enjoy for years to come.

A DIY plywood dining chair offers a fantastic way to personalize your space and hone your woodworking skills. However, for those seeking a more effortless and comfortable outdoor dining experience, consider a stackable sling outdoor dining chair. These chairs offer a blend of durability and comfort, and their stackable design makes storage a breeze.

While a DIY plywood chair can be a rewarding project, a stackable sling chair provides a ready-made solution for relaxed outdoor dining.